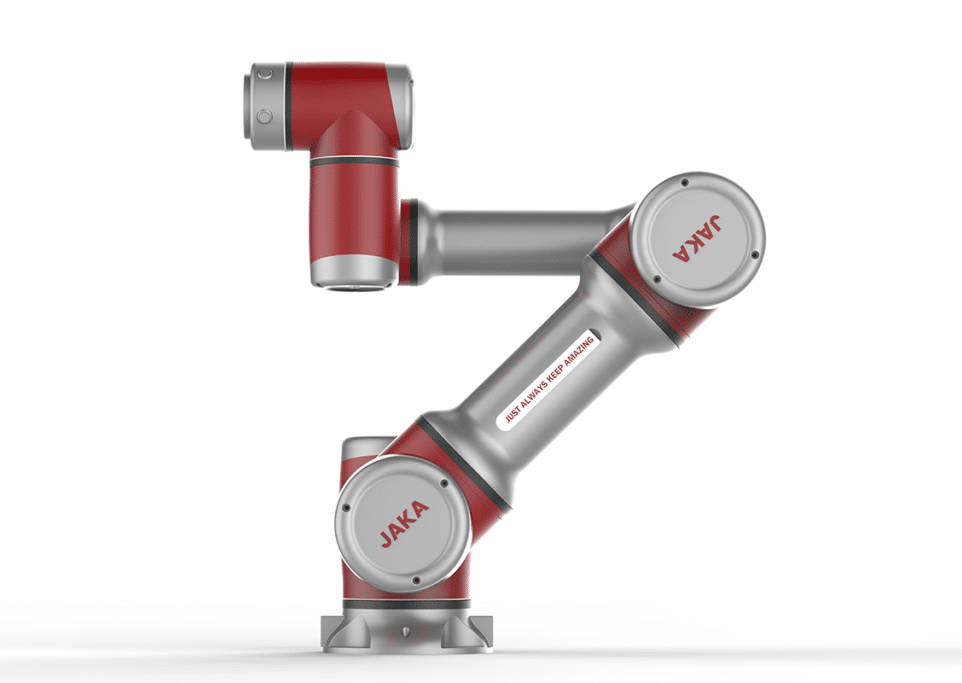

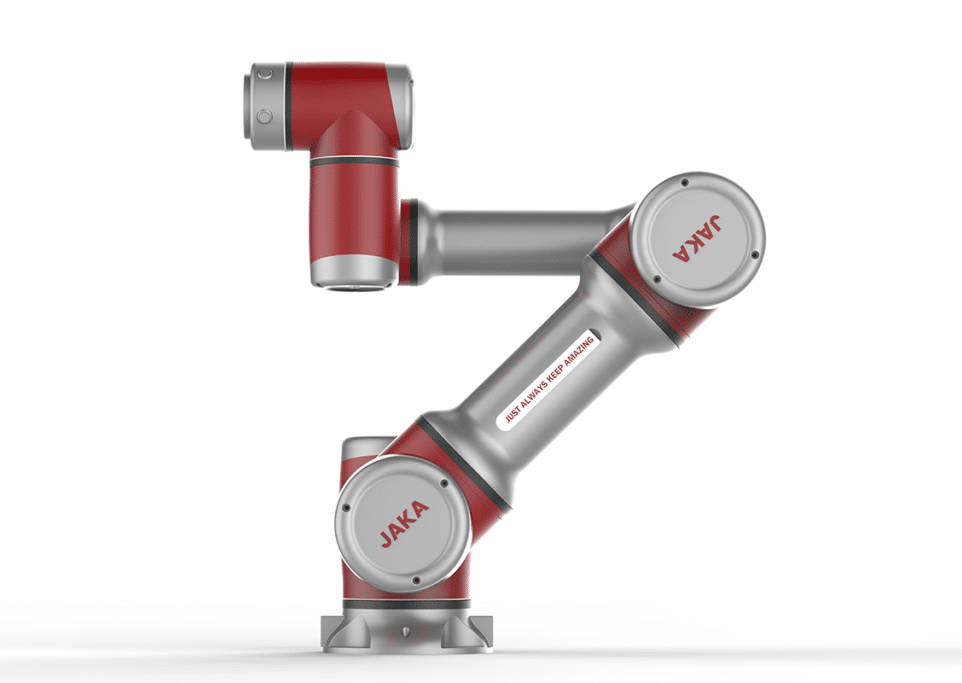

Jaka

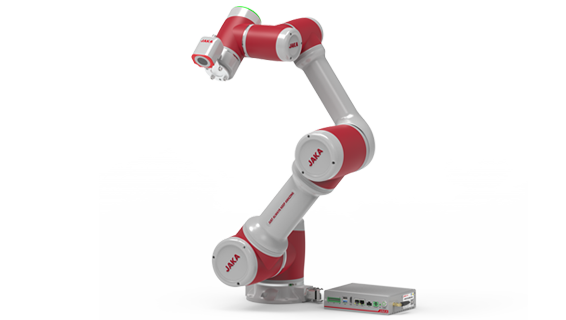

Introducing JAKA’s range of robots. Collaborative, practical & flexible, JAKAs 6DOF range of robots have multiple applications in education and industry

Collaborative, cost-effective & practical

Introducing JAKA’s range of robots. Collaborative, practical & flexible, JAKAs 6DOF range of robots have multiple applications in education and industry

626mm to 1327mm

3kg to 18kg

6

Collaborative/Industrial

In addition to the standard JAKA range of Zu Robots, combine onboard vision systems to your JAKA. By adopting the product design principles of JAKA (Smart, Simple, Small) and integrating advanced robot technoloigies such as wireless teaching, graphical programming and visual protection, it revolutionises the way of Human-Cobot interfaction, improves the safety of human-machine cooperation and greatly reduces the threshold of robots. The AI all in one cobot integrates a plug and play vision to ensure that the natural interaction and autonomous adaptaion between cobot, human and operating environment.

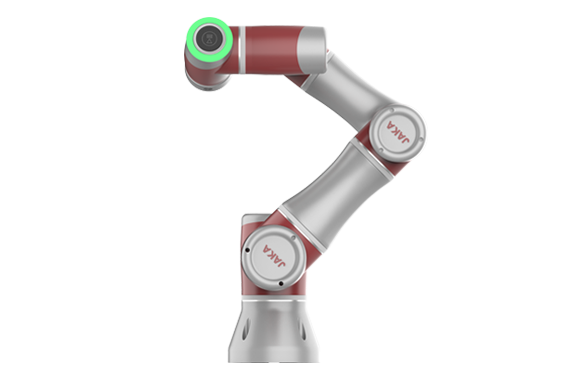

Equipped with advanced industrial force sensors (at the wrist or the base of the robot), the Zu S series can provide better man-machine interaction experience and guarantees safety. A variety of force control solutions such as constant force, normal tracking and speed mode are available.

The ZU series of cobots from JAKA are entry level robots ideal for manufacturing industries including machine tending, injection molding applications and pick and place applications. With custom End of Arm Tooling from POMO Robotics, alleviate manual processes within your factory spaces

JAKA MiniCobo Cobot has the characteristics of lightness, compactness, high flexibility, and easy installation. It uses an integrated intelligent drive module to achieve a lightweight design while having superior performance; in addition, rich secondary development interfaces provide customers with more choices in different scenarios. JAKA MiniCobo Cobot has a small appearance, simple and intuitive operation, low noise, and high cost performance. It is especially suitable for consumption, service, education and other fields.

JAKA AI 5 can be used for PCB Pick and place detection from custom jigs to electronic devices. Equipped with suitable end of arm tooling and a software platform that is run of a computer or IPAD device, JAKA AI 5 can be used for a wide variety of electrical and electronic manufacturing applications

JAKAs collaborative robot range can be equipped with soldering stations to help with auto soldering of PCBs, electronic and electrical equipment. With excellent position repeatability and accuracy, the JAKA range of collaborative robots can deliver excellent process efficiencies

JAKA Robotics can be used for a wide range of end of line packaging solutions for electronics, technology, food and pharmaceutical applications.