Case Erecting

Erect, tape and prepare multiple SKUs at the same time using a wide range of case erecting solutions. We work with leading robot suppliers such as Yaskawa, Kuka, JAKA and Universal Robots to ensure that case erecting applications are safe, meet the cycle times and can deal with the demands of a production environment.

Food Processing

From placing pancakes to halving potatoes or handling chicken nuggets in their trays, POMO Robotics can deliver full turnkey solutions using robotic and non robotic solutions to increase throughput, machine reliability, productivity and help improve the performance of traditional food manufacturing and processing facilities.

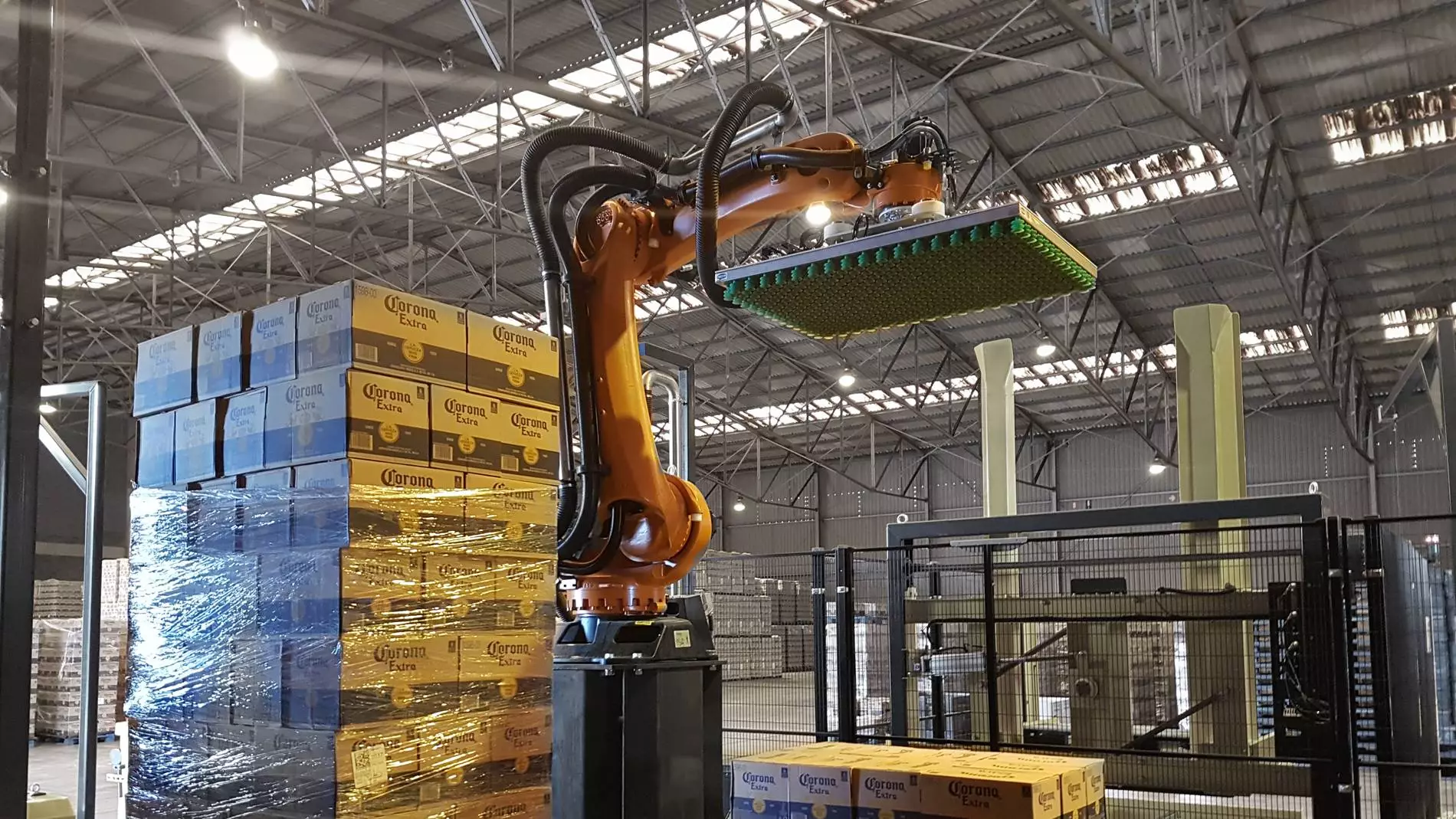

Palletizing

Palletize SKUs into user defined pallet patterns using either industrial or collaborative robots depending on weight and cycle times. Our fully automated palletising solutions can help arrange patterns for SKUs weighing 500kg to 20kgs. As completely autonomous stand alone units and easy to operate and integrate with existing systems

Mixed SKU Palletizing

Have multiple SKUs to palletize? POMO Robotics can develop multi SKU packaging and palletising solutions with a combination of vision systems and robots to ensure for a wide variety of SKUs. As completely autonomous stand alone units and easy to integrate, these cells are built to fit existing factory spaces where possible for both critical and non critical areas

Depalletizing

Using machine vision systems, carry out depalletising of same or mixed SKUs onto conveyors so that there is never a requirement for multiple tool changes, complicated automation systems to serve a single purpose. Ensuring maximum flexibility, POMO Robotics can integrate systems like PICK from Boston Dynamics to for depalletising applications in any manufacturing or production setting in both industrial and collaborative environments

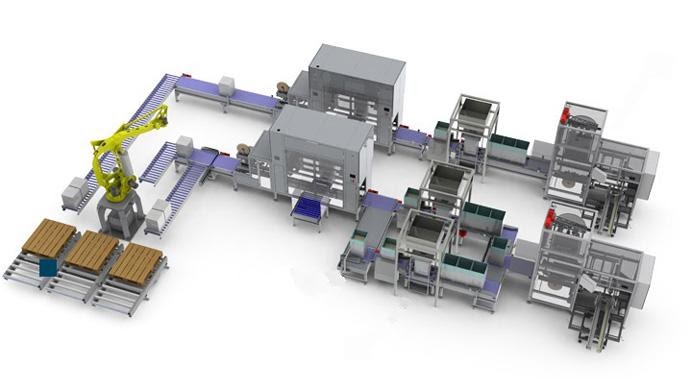

End of Line Packaging

Our bespoke end of line packaging services offer great value for money including custom system design and development, equipment selection such as conveyors, diverters and systems suited to guarantee to meet production speeds. Our bespoke end of line packaging systems can provide great value for money and quick returns on investments

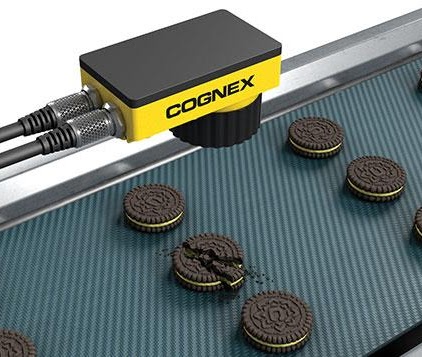

Vision Systems for Food Production

Bring amazing improvements using the power of machine vision and AI to carry out QA inspections on both raw and cooked products. This includes inspection to detect damaged product, mis-shaped, mis-aligned, portion assesment, foreign body detection and much much more to automate the rejection of food waste and save an average of 15% on food waste metrics in your factories and processes

Systems Integration for F&B

With established partnerships in the food and drink processing industry who have been in the food and drink processing market for over 30 years, POMO Robotics can deliver turnkey food and drink processing solutions for a wide variety of snack foods, potato products, dairy, meat and fish. Along with our digital twin capabilities, simulate your digital factory

Lidding Solutions

Automate the lidding of your products using collaborative robots. Save time and effort during the automated operation compared to traditional automation machines with minimal operational downtime and high reliability

Turnkey Services

Unsure how to specify and design your end of line packaging systems from product management to palletising? With excellent industry connections, turnkey experience and the ability to design systems to accomodate packaging solutions for bot automation and semi-automatic systems of varied degress of complexity, POMO Robotics can provide complete turnkey systems including design, build, procurement, system integration, on site installation services, site acceptance testing and long term continued support