Injection Moulding Tending

Relieve machine operators from physically demanding, repetitive work and eliminate the risk of injuries with injection moulding tending applications from POMO Robotics. Using our series of collaborative or industrial robots, machine tending for injection moulding machinery can be automated with the use of custom end of arm tooling solution and can improve productivity, save time, money, and address labour scarcity issues. Take advantage of robotic demoulding, robotic de-gating, robotic nippers, robotic cutting and general pick and place. Furthermore, all our solutions are compatible with EUROMAP 67 or similar and with our turnkey installation packages you can be rest assured that no additional work is required once our installations are complete. Need custom tooling developed to automate your applications? Speak to us today.

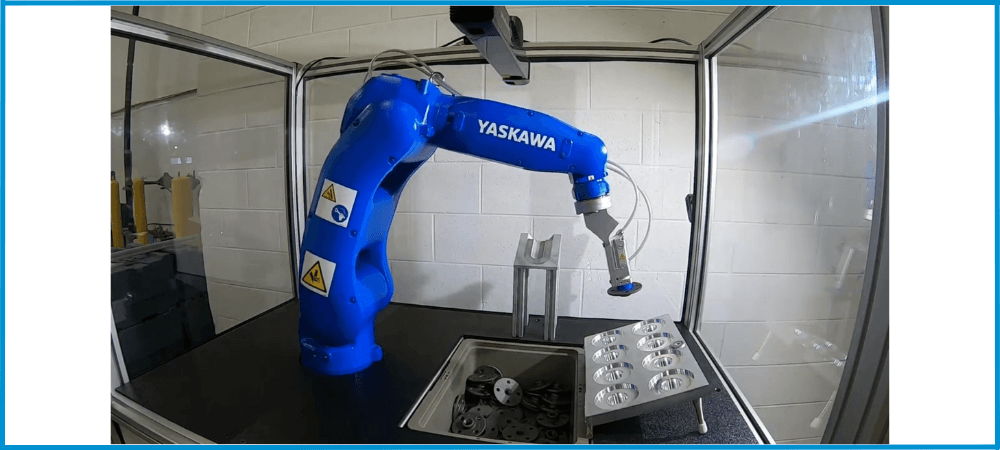

Robotic Welding

Automate your welding processes with better precision, accuracy and with less defects using the power of robots. Our solutions for robot welding include development of custom jigs and fixtures, TIG and MIG welding solutions, spot welding, material handling during welding all carried out with an easy-to-use software program that can ensure you never experience downtime. The use of robots for welding can allow for precise and amazing results which result in less waste, greater safety and enhance accuracy. We work with leading brands such as Yaskawa, KUKA and JAKA that can ensure that their 6 degree of freedom robots can offer precise welding applications in the form of custom or off the shelf welding solutions. Speak to us today to see how we can help.

CNC Machine Tending

This is the most common forms of robotic automation solutions. Using both collaborative and industrial robots to carry out a wide range of automation activities for CNC milling and turning applications including machine loading, unloading, post processing measurements, post processing accuracy checks, onboard part storage and much more our solutions can help an average productivity improvement of at least 30%. Our offerings of robots and custom end of arm tooling options from POMO Robotics ensure that we can automate the mundane and often dangerous task of CNC machining tending applications. Our software interfaces and the ability for our robots to work with common embedded packages with standard CNC machines can help accelerate the adoption of robotic automation within your business freeing up personnel to focus on more productive activities within your factory.

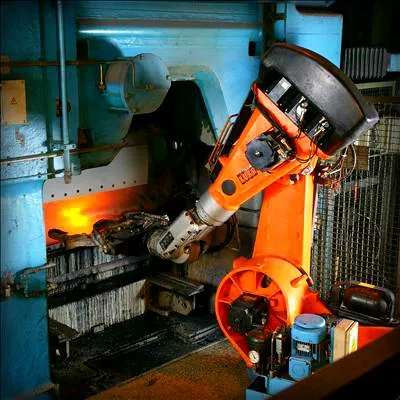

Foundry Robots

Improve the quality of your foundry applications with the use of bespoke automation solutions. Foundry robots can handle a wide range of payloads up to 1500kg and have a wide range of specialist functions such as high torque wrists which means that industrial robots can safely handle bulky payloads at every step. Using specialist counterweights, drives and motors including specialist links and capable of working in high temperature environments; automate common foundry applications such as handling of delicate moulds, casting extraction operations, ladling of molten metal, core assembly and setting, ladling of cooling metal, deburring, grinding and polishing. With our custom hardware and software solutions with dedicated OEMs, programming and reprogramming our robots are easy and can handle any production objectives that you may face.

Robotic Sanding

Automate finishing, polishing tasks with sanding solutions from POMO Robotics. With custom end of arm tooling designed for sanding and polishing applications from OnRobot or Dynabrade you can completely automate the process of sanding down wood, metal, carbon fibre, synthetic materials to provide a smooth finish similar to a hand finished product. What’s more; custom programming including tool path definition allows for sanding down of key surfaces and materials.

Adhesive Dispensing

Accurately dispense adhesives with our cobot glue dispensing applications. Key to an effective dispensing application is accuracy and repeatability. Cobots and industrial robots equipped with the right end of arm tooling from POMO Robotics, can help with the dispensing of adhesives in set patterns by defining the robot path, ensure accurate dosage or dispensing using force feedback applications and additional pressing equipment to ensure that the adhesive has set. Rest assured all our robotic solutions for glue dispensing can form part of an assembly line activity.

Case Packing

Automate your end of line activities with case packing applications from POMO Robotics. Robots that we work with including JAKA and YASKAWA equipped with custom end of arm tooling from us can ensure that cycle times for packing boxes, crates, trays and even bins can be sufficiently and tightly packed. We also provide solutions in weighing, case splaying and provide labelling robots that can accelerate the end of packing solutions that you require.

Palletising

Palletise your products into user defined pallet patterns or auto generated using either industrial (for heavier payloads) or collaborative robots (for lighter payloads). We can achieve your target cycle time and with our fully automated solutions and safety features, our palletising solutions can help address productivity and reduce the manual effort required to palletise products. We can palletise a wide range of packaging materials including cardboard boxes, trays, bins and storage containers.

Bin Picking

With a combination of 3D Vision and machine learning algorithms, automate the requirement to carry out bin picking applications with the use of our fully system integrated bin picking solutions combining custom end of arm tooling, vision systems, safety systems, custom jigs and fixtures. Simply upload the CAD file of your part, identify the pick location and let the robot do the rest. Our 3D Vision cameras look for the required geometries and identify the pick location before accurately picking out the parts from any size bin. With fast cycle times and improved accuracy, there has never been a better time to investigate the use of bin picking for factories.

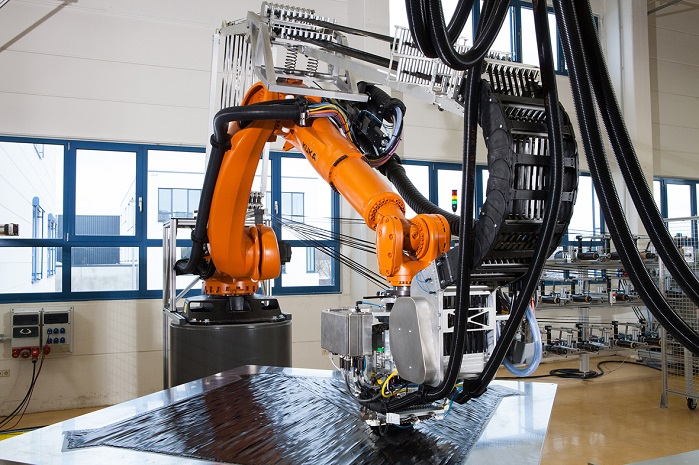

Automated Fibre Placement

With the advancements in additive manufacturing, automated fibre placement robots can dispense carbon fibre tows, heat and compact to form complex geometries that are in demand for the aerospace and defence industries. Our AFP solutions also combine unique industrial robots, complex End of arm tooling for quicker deployment of fibre placement robots. If you are considering advanced materials and want to make more complex geometries using industrial robots, speak to us today.

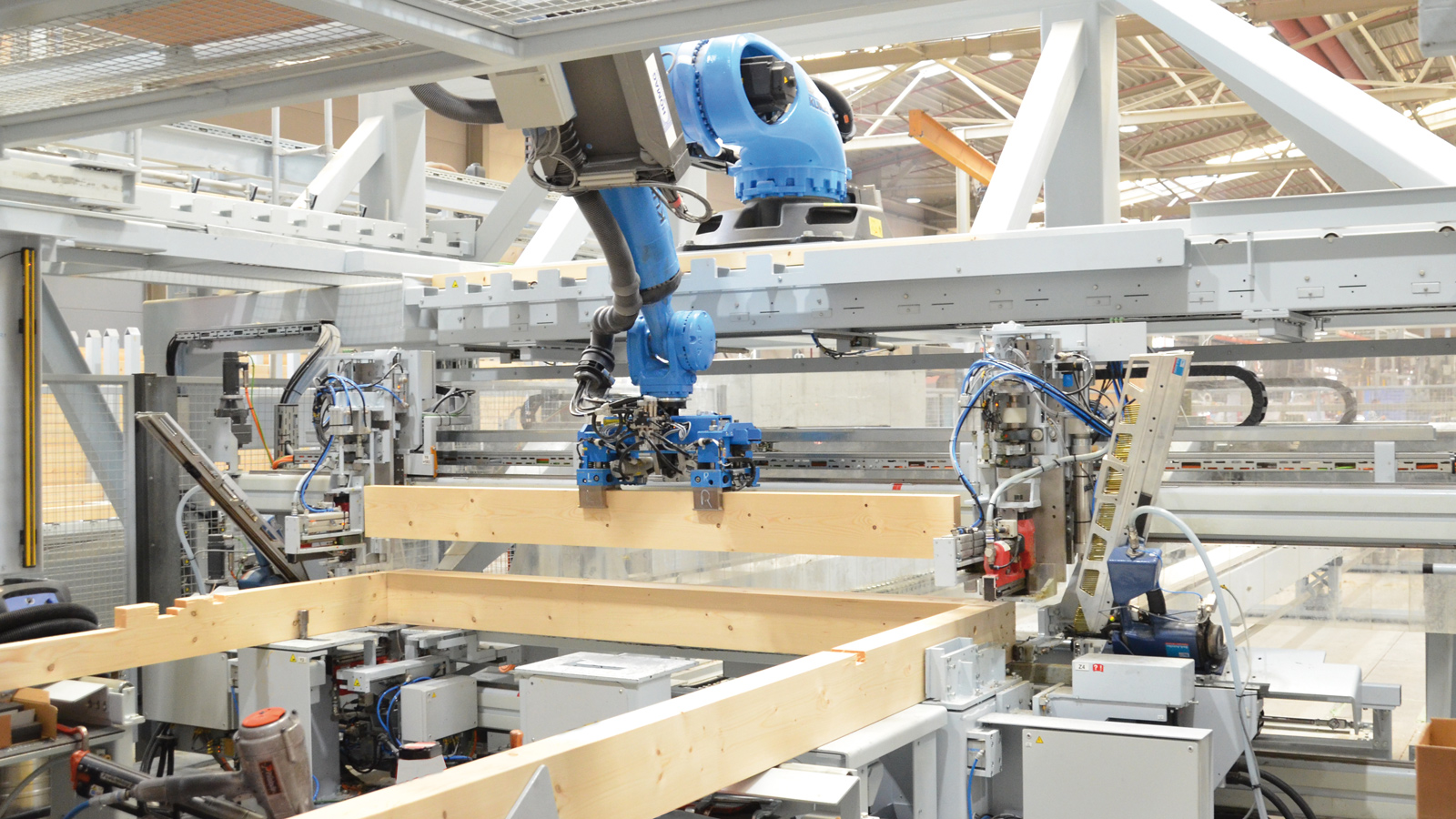

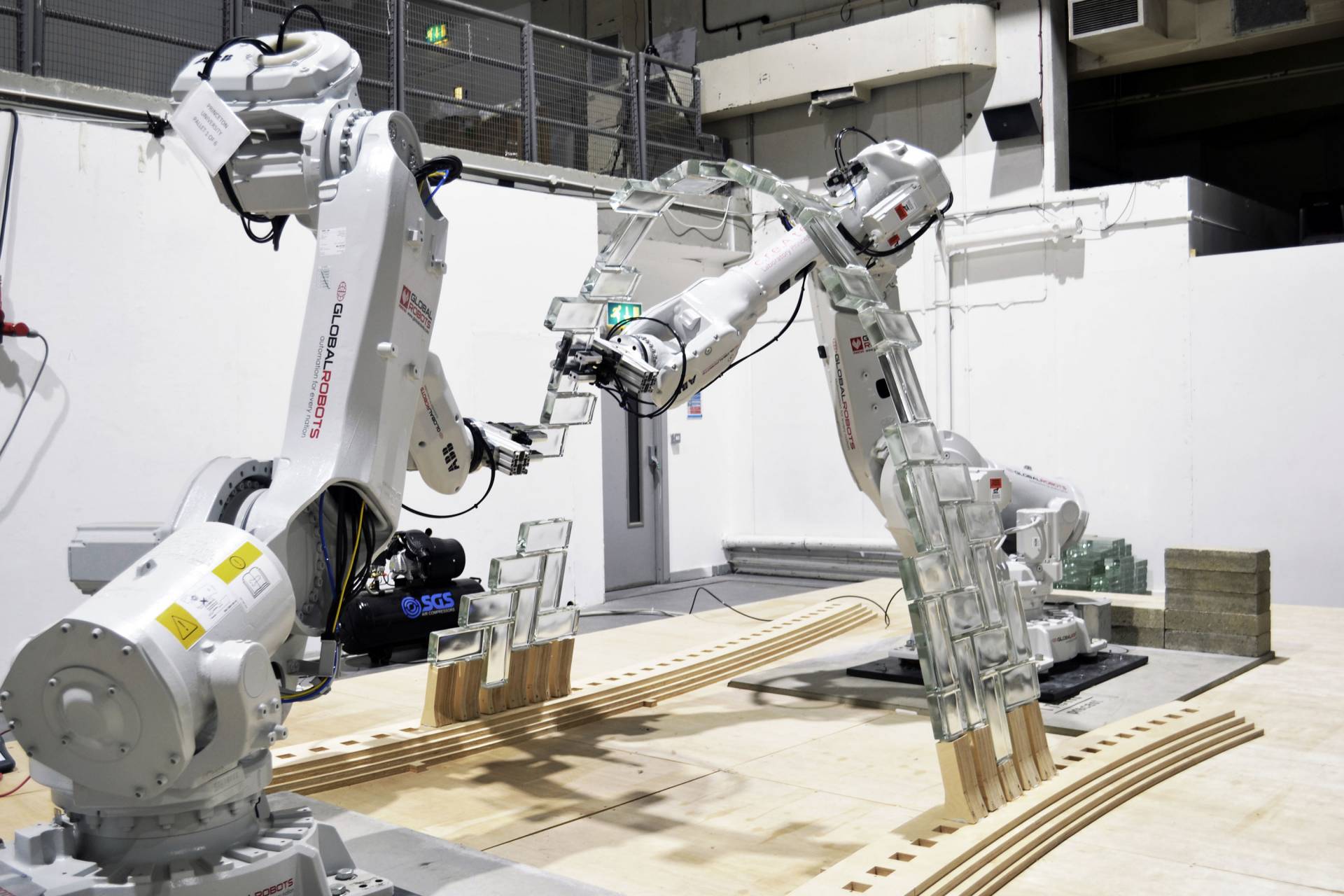

Robots for the Timber Industry

Our turnkey robotic solutions for the wood and timber industry include pick and place of plywood stock, palletising, cutting, grinding, polishing, finishing, adhesive dispensing and with our range of material handling robots, transfer materials between factory spaces for pre and post processing applications.

Robots for the Glass Industry

Using robots, automate the requirement to inspect glass, pick and place, cut, grind and polish with custom end of arm tooling applications. We also provide solutions in material handling and automated glass quality inspection applications.

Robots in Furniture Manufacturing

Do you have custom sanding and finishing applications during furniture manufacturing? We can provide solutions in robotic sanding, finishing, adhesive dispensing, fabric cutting, quality inspections, bolt tightening and robotic screwing to ensure that these repetitive and mundane activities are completed without the need for human intervention.