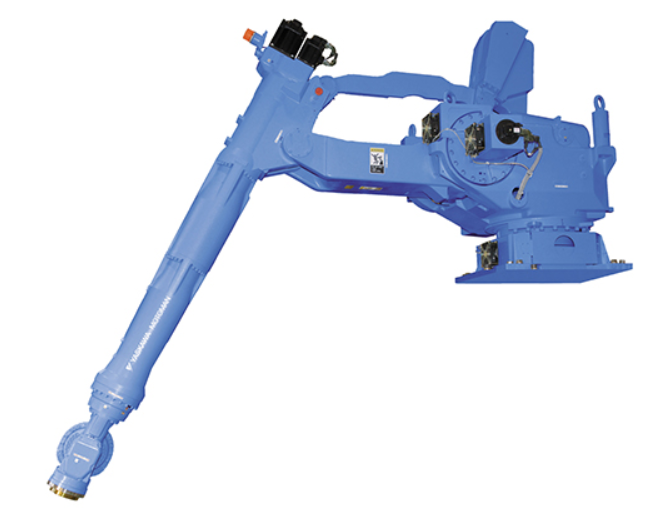

Yaskawa UP Series

- Payload Range: 400kg

- Reach: 4909mm

- DOF: 6

Designed to handle a variety of materials, UP-series robots provide flexible and superior performance in high-payload material handling and part transfer applications.

Agile Robot Performance

Better Floorspace Utilization

-

Slender, space-saving design enables work in tight spaces.

-

Extended reach models provide a large work envelope for tending multiple processes.

Increased Production Throughput

Find out more

Yaskawa AR Series

- Payload Range: 8kg to 20kg

- Reach: 1312mm to 5622mm

- DOF: 6

Offering the highest payload, fastest speed and highest wrist allowable moment in their class, six-axis AR-series robots optimize productivity. These high-performance arc welding robots are compatible with the easy-to-use Universal Weldcom Interface (UWI) pendant application that enables full utilization of the advanced capabilities of select welding power sources without putting down the robot programming pendant.

Key Benefits:

Increased Output and Product Quality

Find out more

Yaskawa MA Series

- Payload Range: 6kg

- Reach: 5616mm

- DOF: 6

Designed for highly-efficient welding performance, six-axis MA-series robots can increase productivity and improve part quality.

Increased Reliability and Safety

Streamlined Robot Design

-

Facilitates easy torch access into confined spaces and avoids potential interference with fixtures.

-

Enables close proximity placement for high density layouts.

-

Slim profile designs facilitate high-density spacing and reaching into confined spaces.

Robust Welding Performance

Find out more

Yaskawa MC Series

- Payload Range: 50kg

- Reach: 3161mm

- DOF: 6

Engineered with high rigidity and precision drives for superior path accuracy, MC-series robots are ideal for laser cutting, laser welding, plasma cutting and dispensing applications.

Performance-Driven Design

-

Higher payload for remote laser welding head, or higher path accuracy when using welding or cutting laser head.

-

Slim profile design improves part accessibility and allows close proximity placement for high density layouts.

Highly-Accurate Performance

Increased Production Throughput

Find out more

Yaskawa MS Series

- Payload Range: 88kg to 100kg

- Reach: 3751mm

- DOF: 6

Highly reliable, six-axis MS-series robots are controlled with the DX200 controller, delivering fast and accurate performance for spot welding applications.

Optimizes Production Rates

Enhances Application Flexibility

Reliable Robot Performance

Find out more

Yaskawa SP Series

- Payload Range: 80kg to 235kg

- Reach: 3751mm to 4782mm

- DOF: 6

Highly reliable, the six-axis SP-series robots are controlled by the YRC1000 controller, delivering fast and accurate performance for spot welding applications.

Optimized Production Output

Superior Robot Design

-

Wide wrist motion range eliminates interference.

-

Slim profiles facilitate high-density spacing and reaching into tight spaces.

-

Integrated spot harness optimizes wrist flexibility and reduces downtime.

Greater Application Flexibility

-

A variety of payloads and reaches available to support a wide range of tasks.

-

7-axis, hollow-arm and shelf-mounted models available.

Find out more

Yaskawa MPK Series

- Payload Range: 2kg to 5kg

- Reach: 1551mm to 1625mm

- DOF: 6

eliable and agile, these 4- and 5-axis robots provide high performance for a variety of applications including case packing, part transfer, pick and place, and palletizing.

Vast Application Possibilities

Highly-Reliable Operation

Versatile Design Options

Find out more

Yaskawa MPL Series

- Payload Range: 80kg to 800kg

- Reach: 3024mm to 3291mm

- DOF:4 and 5

Applicable for a variety of industries such as food and beverage, consumer packaged goods and more, MPL-series robots make moving boxes and filling pallets easy, while offering a high ease of maintenance. Highly efficient and reliable, these robot models are ideal for case palletizing, bag palletizing, order picking, depalletizing and other handling tasks.

Performance-Driven Design

Maximized Reliability

Beneficial Application Options

Find out more

Yaskawa MPP Series

- Payload Range: 3kg

- Reach: 300mm to 600mm

- DOF:Delta

Nimble, accurate and efficient, MPP-series delta robots are ideal for assembly, cartoning, kitting, pick and place, and packaging tasks.

Fast and Precise Performance

High-Density Workspace Layouts

Greater Application Flexibility

-

NSF-H1 certified food-grade lubricants and anti-corrosive coating enable the handling of a wide variety of products.

-

Available with advanced technologies like MotoSight™, MotoPick™ and conveyor tracking.

Find out more

Yaskawa PL Series

- Payload Range: 5kg to 20kg

- Reach:1118mm to 2590mm

- DOF:15

Well-suited for a wide range of industries, extremely versatile PL-Series robots help to optimize throughput for a variety of handling applications. Ideal for palletizing, order picking, and logistical tasks for end-of-line or distribution automation, these highly efficient models can move boxes and fill pallets with ease and precision.

Powerful Capability

Optimized Reliability

Advantageous Application Options

Find out more

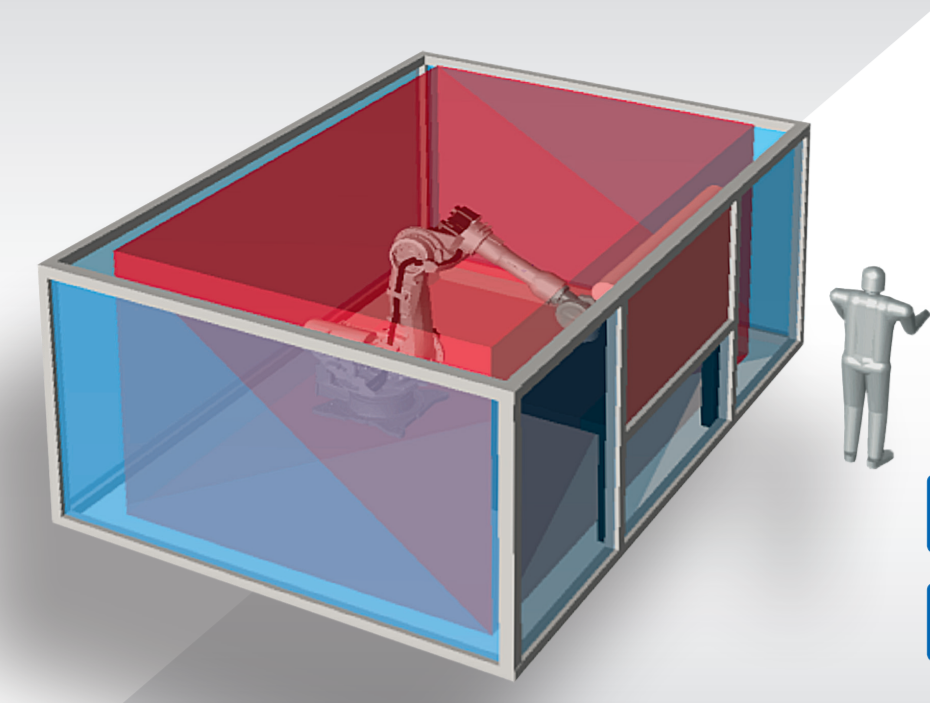

Yaskawa EPX Series

- Payload Range: 5kg to 20kg

- Reach:1852mm to 4582mm

- DOF:6

Ideal for painting, dispensing and other industrial coating tasks, six-axis EPX-series robots create smooth, consistent finishes with outstanding efficiency.

Factory Mutual Approved

Outstanding Painting Efficiency

Enables Layout Flexibility

Find out more

Yaskawa MPX Series

- Payload Range: 130kg to 200kg

- Reach: 2629mm to 4151mm

- DOF:6

Optimized for painting, dispensing and powder coating applications, six-axis MPX-series robots create smooth, consistent finishes with high efficiency.

Factory Mutual Approved

Consistent and Efficient Painting Capability

Facilitates Layout Flexibility

Find out more