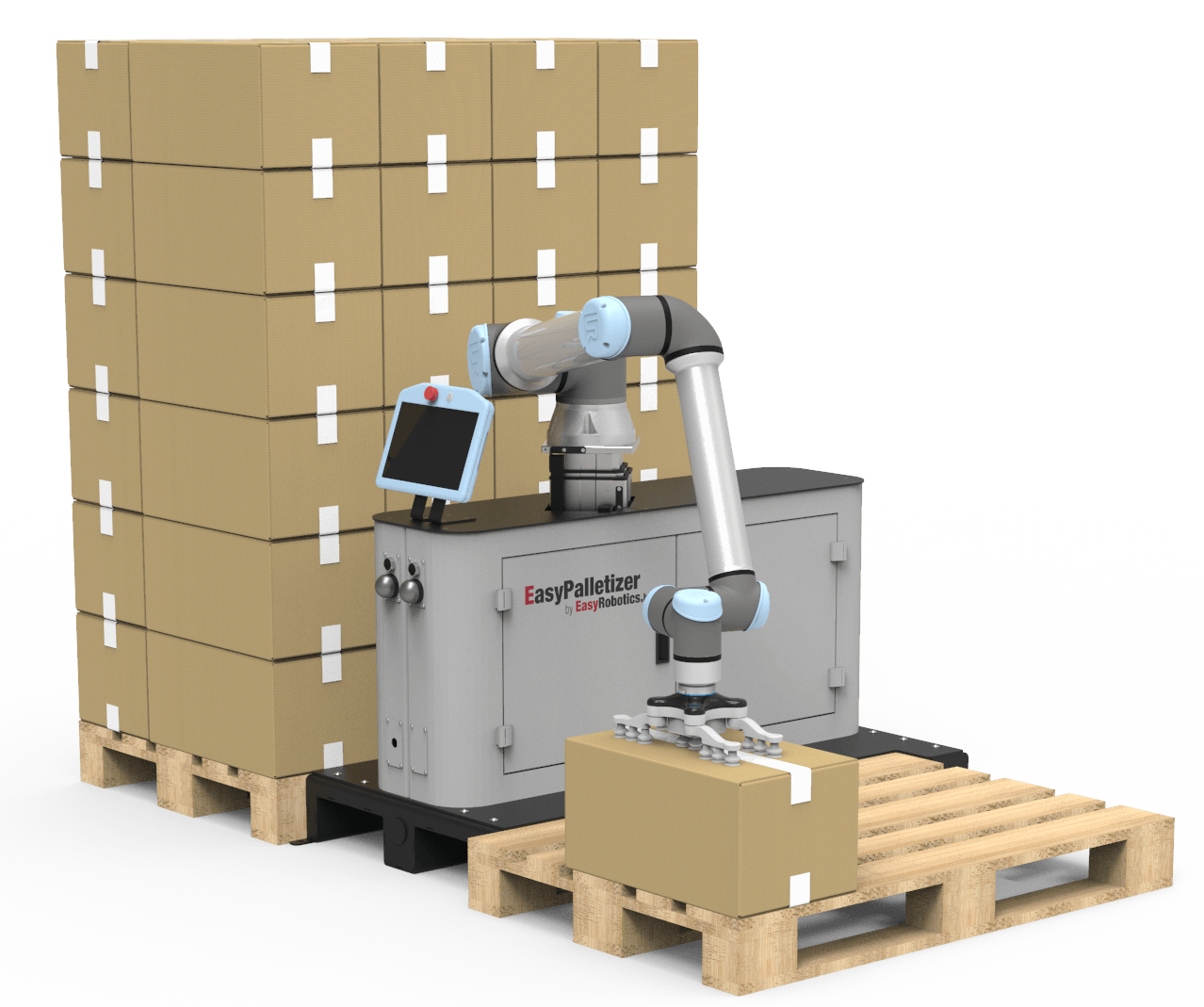

Palletizing

Palletize SKUs into user defined pallet patterns using either industrial or collaborative robots depending on weight and cycle times. Our fully automated palletising solutions can help arrange patterns for SKUs weighing 500kg to 20kgs. As completely autonomous stand alone units and easy to operate and integrate with existing systems

Mixed SKU Palletizing

Have multiple SKUs to palletize? POMO Robotics can develop multi SKU packaging and palletising solutions with a combination of vision systems and robots to ensure for a wide variety of SKUs. As completely autonomous stand alone units and easy to integrate, these cells are built to fit existing factory spaces where possible for both critical and non critical areas

Depalletizing

Using machine vision systems, carry out depalletising of same or mixed SKUs onto conveyors so that there is never a requirement for multiple tool changes, complicated automation systems to serve a single purpose. Ensuring maximum flexibility, POMO Robotics can integrate systems like PICK from Boston Dynamics to for depalletising applications in any manufacturing or production setting in both industrial and collaborative environments

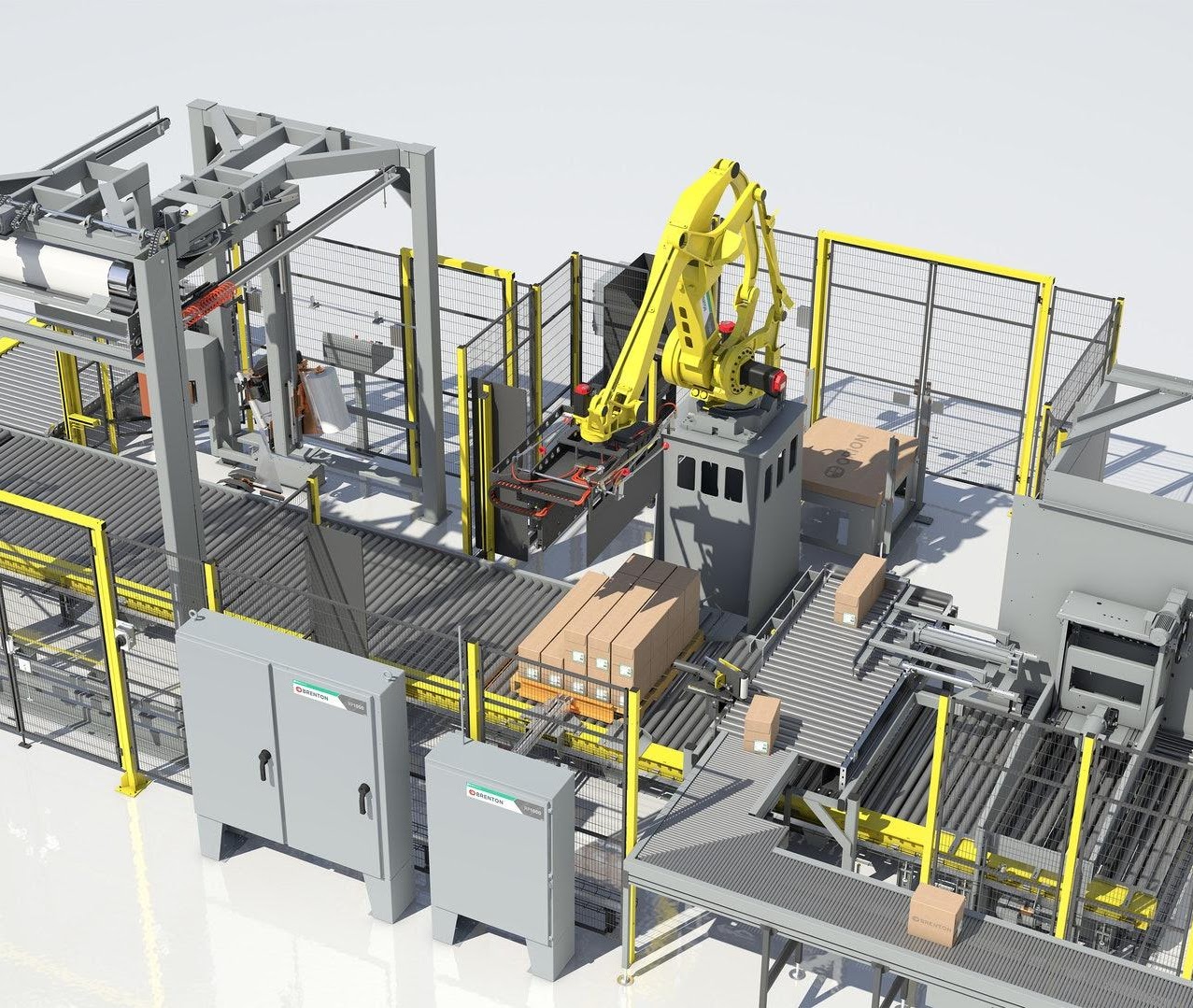

End of Line Packaging

Our bespoke end of line packaging services offer great value for money including custom system design and development, equipment selection such as conveyors, diverters and systems suited to guarantee to meet production speeds. Our bespoke end of line packaging systems can provide great value for money and quick returns on investments

Labelling Systems

Automate labelling of boxes in situ, at end of line packaging stations or on pallets with our range of end of arm tools, robotic sliders, custom end of arm tooling and conveying solutions.

Case Erecting

Mundane tasks such as case erecting can be done automatically using industrial and collaborative robots. With our custom end of arm tooling solutions, custom jig and fixtures development, case erecting can be automated and conveyed for end of line packaging solutions

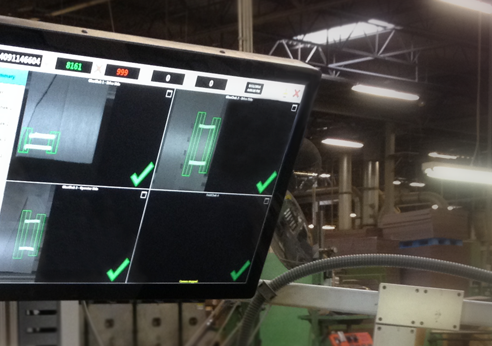

Vision System Integration

Bring amazing improvements using the power of machine vision and AI to carry out reading of barcodes, text, box condition and much more to seamlessly integrate robots and automation systems.

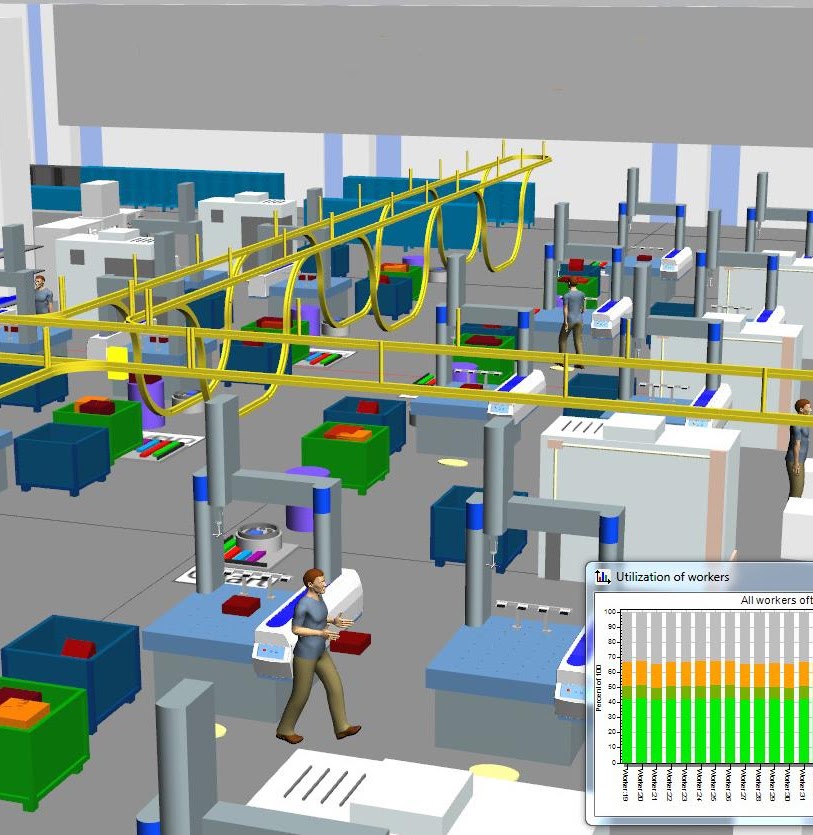

Custom Packaging Solutions

Unsure on how to get started with packaging solutions? In association with our OEM Partners, POMO Robotics can develop custom end of line packaging and palletising solutions that meet target throughput and cycle times

Remote Operating Stations

Struggling for space with robots? Our range of remote operating stations, custom end of arm tooling development and AGVs equipped with high performing sensors, POMO Robtoics can develop custom mobile autonomous operating station solutions which can navigate workshop spaces with ease, have high degrees of accuracy and perform better than human operators on site

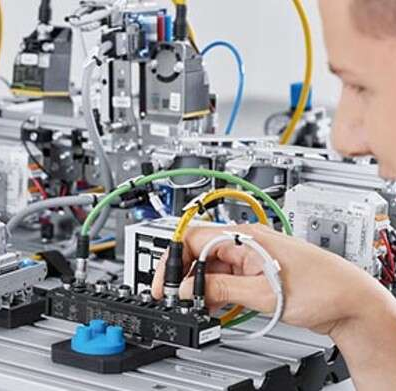

Bin Picking Applications

With a combination of vision system for QA/QC inspections, part identification and dextrous arms, bin picking is one of the most challenging automation projects when working with Robots. POMO Robotics can develop custom bin picking applications for your businesses and process together with our vision system partners