Unsure where to start? We can help...

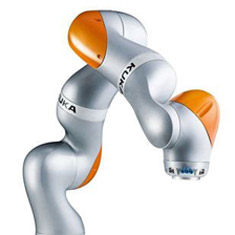

Automating a process or a sequence of tasks can be a daunting task both from a technical and commercial point of view. We can help you determine whether Automation is right for you.

POMO Robotics offers a free, no-obligation Application Assessment service to find out if robotic automation is for you. We look at tasks from both a robotic and automation point of view in 6 steps. Take a look at our steps below: