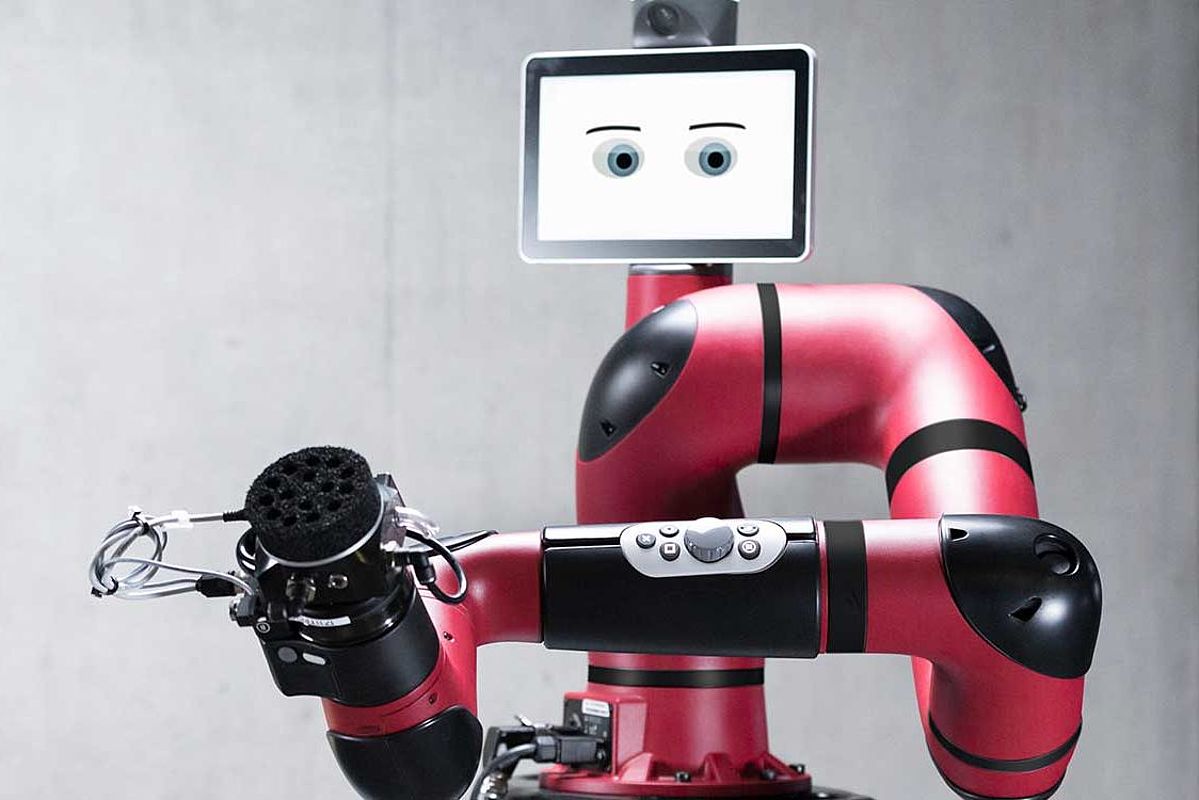

Collaborative robots, also known as cobots, are designed to work alongside humans in a collaborative manner. These robots are typically smaller and lighter than industrial robots, and are designed to be safer around humans. They often have built-in safety features, such as force-sensing technology, that allow them to stop or slow down if they come into contact with a person or object.

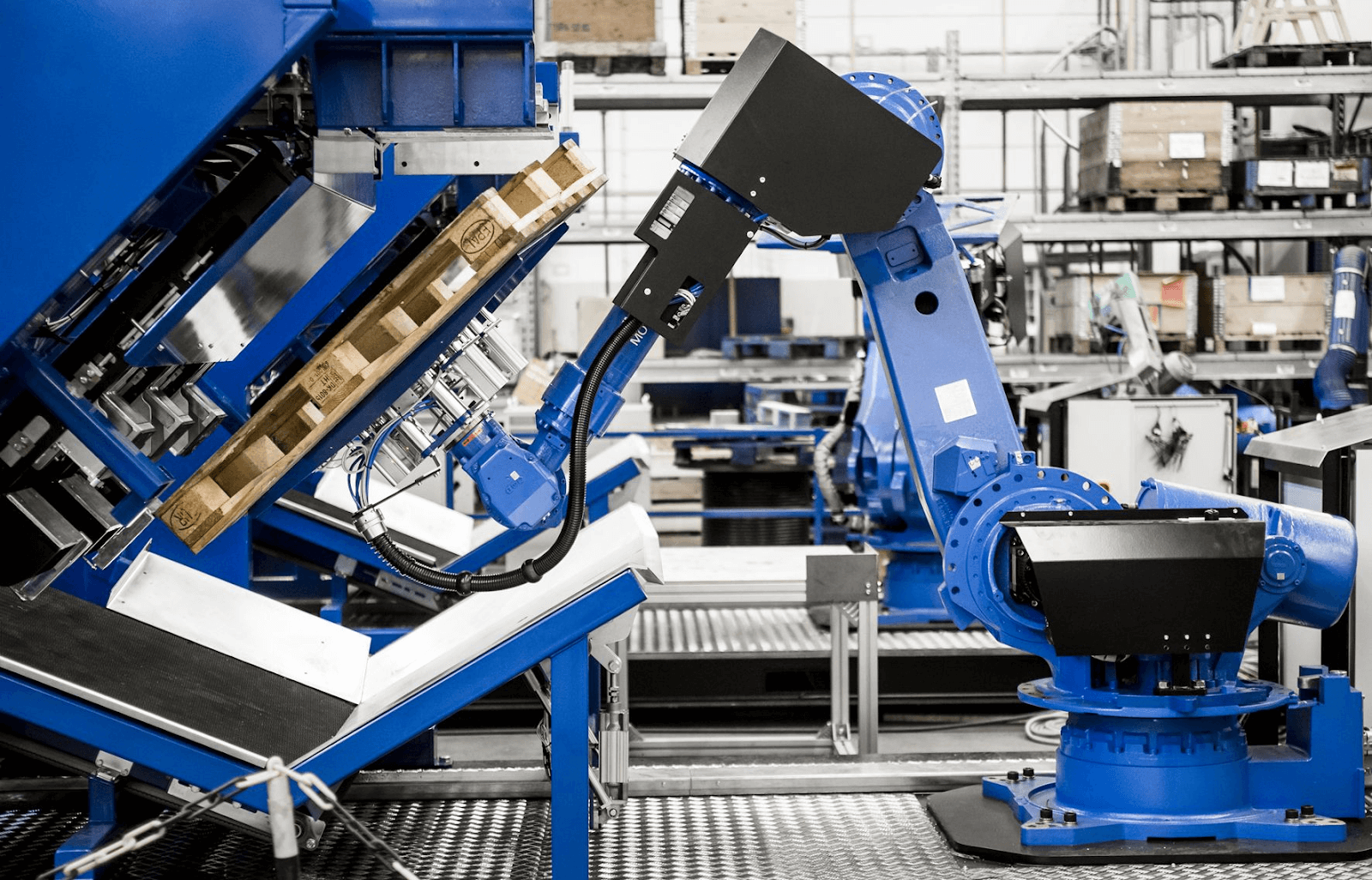

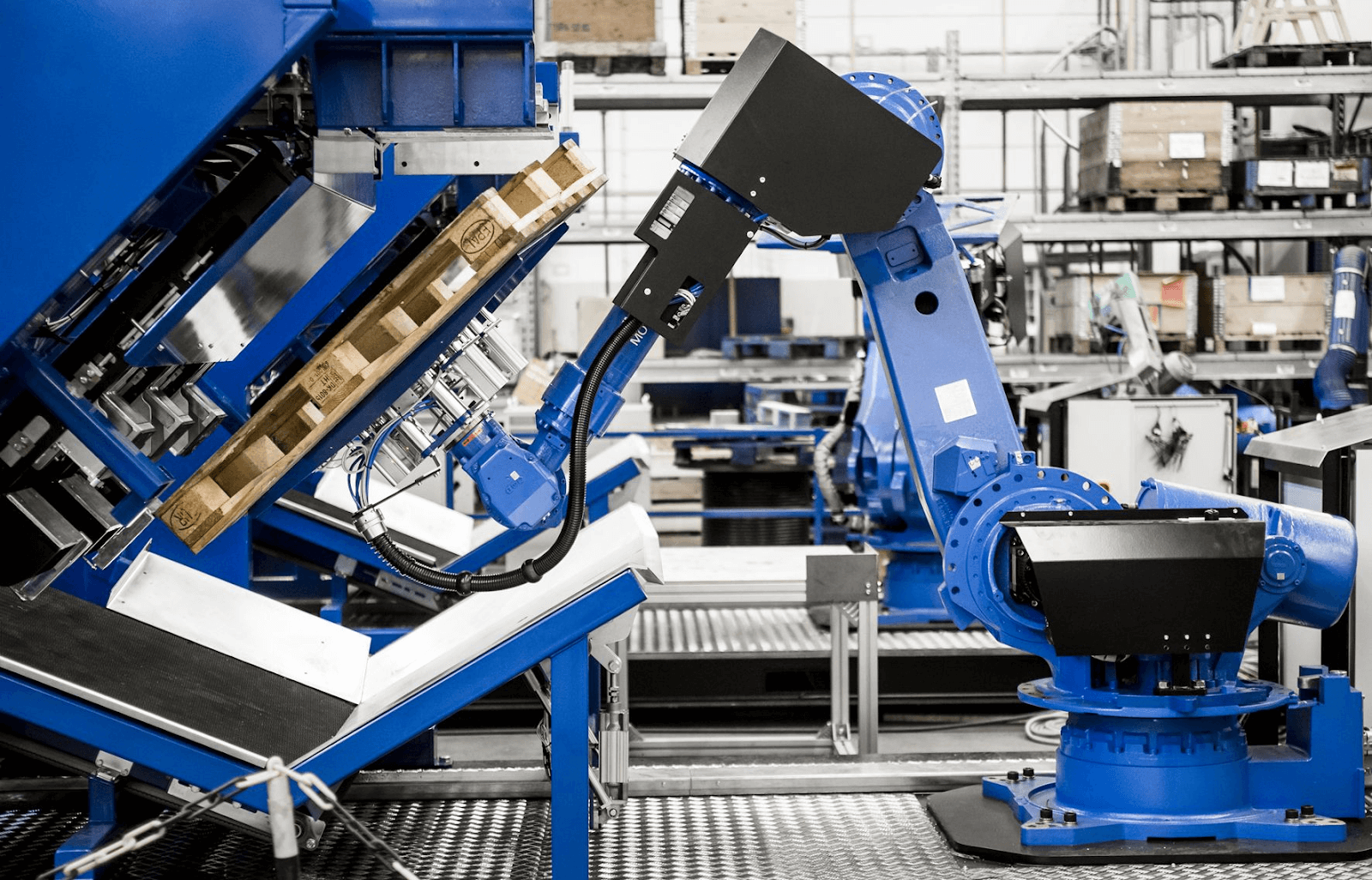

Industrial robots, on the other hand, are typically larger and more powerful than collaborative robots. They are designed for tasks that are too dangerous, repetitive, or physically demanding for humans to perform, and are typically used in manufacturing and other industrial settings. These robots are often used in assembly lines, welding, painting, and other tasks that require a high degree of precision and speed.

One key difference between collaborative and industrial robots is their level of autonomy. Collaborative robots are often programmed to work in close proximity to humans, and require human operators to guide them through their tasks. Industrial robots, on the other hand, can be programmed to work autonomously, without human supervision.

Another difference between collaborative and industrial robots is their cost. Collaborative robots are often more affordable than industrial robots, making them accessible to small and medium-sized businesses that may not have the resources to invest in industrial automation.

NOW READ THE LONG VERSION!

Let’s start with something simple. What exactly is an Industrial robot and how are they different?

Collaborative Robots or COBOTS as they are more popularly known are robots that are capable of working alongside humans. These robots are fitted with sensors on either all or some of their joints to allow for safe interaction with humans. Advances in materials technology and electronics have allowed for OEMs building cobots such as JAKA and Universal Robots to extend the reach and payloads of cobots operating within industry. These robots are designed to operate safely around humans and their on board sensor technology allows for safe operation. Most collaborative robots operating within industry do not require additional guarding or fencing when they are in regular operation.

However, COBOTS do have their limitations, most cobots work at a higher cycle time (in comparison with industrial robots) and their accuracies can vary depending on the kind of application you are using it for. This is because the robot is not only considering the task it needs to do but also ensuring that it is operating in a desired speed which does not jeopardise human operators who are working next to it. These are mostly suited for pick and place applications, palletising and some cobots are even used for light welding duties as well.

Some cobots from KUKA and YASKAWA for example can be fitted with area scanners or additional sensors which allow the robot to slow down as humans approach close to it. This gives operators additional comfort knowing that these machines are working to the best of their ability with humans working alongside safely. Your system integrator such as POMO Robotics can help select the right cobot for your application.

To be classed as a Cobot, all collaborative robots must comply to ISO 10218-1 and ISO 10218-2. Keep checking this page for further updates regarding the standard. Read more about these standards. Click here.